Extra equipment for 2K flat

and structural road marking

Extra equipment for road marking machines is determined for creating of two component cold plastic structural, flat marking or marking with a profile. For this there is necessary to use so called "special shoe". Structural marking and marking with profiles are usually used for those projects demanding long lifetime period of road marking, also requiring the retroreflection class II (retroreflection during night and rain), and the noise effect mentioned above.

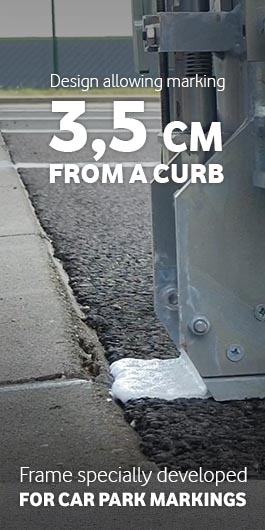

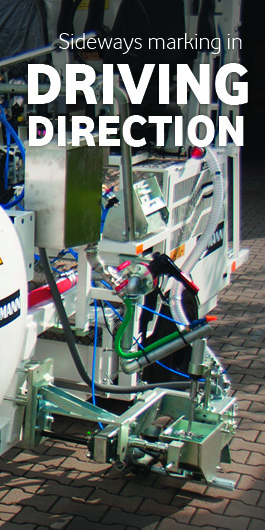

2K Cold Plastic Open Screed Box System location on

RIGHT or LEFT SIDE

Two component cold plastic means a mixture of "A" component (for example Bascoplast fein BA) with "B" component (hardener). This mixture is then applyed on a road surface as a structural or flat marking or marking with profiles. The usual mixing ratio in this case is 100:1. When adding other components as glass beads the final mixing ratio can be 100:3.

"A" component stored in a tank flows to the "shoe" under pressure. Inside the shoe "A" component is being mixed with hardener (with or without additional components as glass beads). Finally when the shoe opens, this mixture is applyed on a road surface with a help socalled "hedgehog".

Parameters affecting quality and method of marking

Parametes mentioned below can not be generally pre-defined. It is essential to adjust them for each project or its part individually.

- viscosity of used material

- matter height in the shoe

- road marking machine speed

- speed of rotating hedgehog

- shoe and hedgehot setup

- shoe parallel position in relation to traffic road

- speed rotation and position of a stirrer

Electronic settings for markings with profiles

The marking with profiles means a line with cross profile used for intended noise effect while you are driving over the line with the profile. All this is can be managed by electronic unit setting.

Remarks and observations

When neglect any detail of two component cold plastic marking you might end up cleaning all parts coming into contact with marking material, which is unpleasant and very time consuming. Transfers to the other spot can cause unwanted material hardening inside the shoe and could blow up time necesary for the marking.

In order to ensure smooth marking course it is appropriate to put emphasis on reduction of stand times. Using used oil or lubricating fat should make the cleaning easier. For better maintenance you might use also paper inserts. Before each marking job starts it is essential to lubricate the inside of the shoe and also the mixing propeller, the hedgehot should be washed thoroughly in a solvent.

Downloads:

![]() Extra equipment for structural road marking

Extra equipment for structural road marking