Special road marking machine adjustments

|

|

|

|

All-inclusive-package: Transport trucks for one H33-3 each. (Image 1). Supply trucks with two preheaters type ID1100-1 with direct supply from the truck – without power station (Image 2). Transport Truck equipped with premarking unit Image 3).

|

|

|

|

Combi-Machine H33-3 with pressurised container (600 l) for thermoplastic extruder, 50 cm and sprayable thermoplastics as well as H33-3 with pressurised container (300 l) for thermoplastic extruder, 50 cm and sprayable thermoplastic + cold paints Airless (385 l) (Image 1). Additional extension of seat support with direct seat above the extruder (Image 2). Mudguard system against pollution as well as a sturdy aluminium roof and comfort seats (Image 3).

|

|

|

|

H18-1 with split frame for use of different application units (Images 1-3).

|

|

|

|

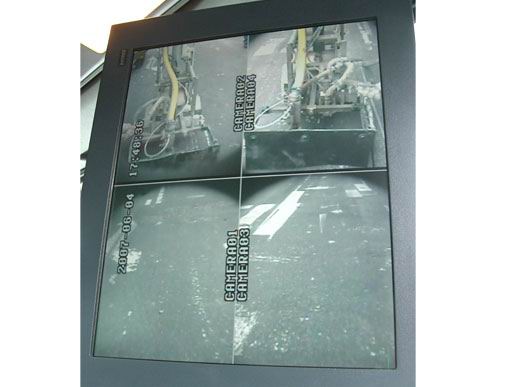

Two-sided camera system with pneumatic device to prevent lense clouding and blurring, for example mounted at a roadmarking truck with sprayable thermoplastics equipment for ensuring accurate marking application, i.e. correct line beginnings and endings. (Image 1-2) Two-sided camera system: 4-channel monitoring system in drivers cabin (Image 3).

|

|

|

|

Simply palletizable (exchangeable) system incl. electric, hydraulic and pneumatic quick opening devices (fittings for thermoplastic systems) (Image 1). Simply palletisable (exchangeable) system incl. electric and hydraulic quick opening devices as well as brackets for quick exchange of application units via forklift (for H18, H26 and H33) (Images 2-3).

|

|

|

|

90 cm airfield marker unit, marking in one pass, on a H18-1 and on a H26-3, also mountable on a H33-3 (Images 1-3).

|

|

|

|

|

|

|

|

Protective cover for extruder systems (Image 1), for MultiDotLine® extruder (Image 2), for electronic spacing device e.g. MALCON4 (Image 3) as well as for the HOFMANN universal pump system (Image 4).

|

|

|

|

Marking machine equipped with dryer unit (Image 1). Blower output approx. 2x10.000 l/min at 600° C (Image 2). Using a H18-1 as an example incl. MultiDotLine® extruder 30 cm (Image 3).

|

|

|

|

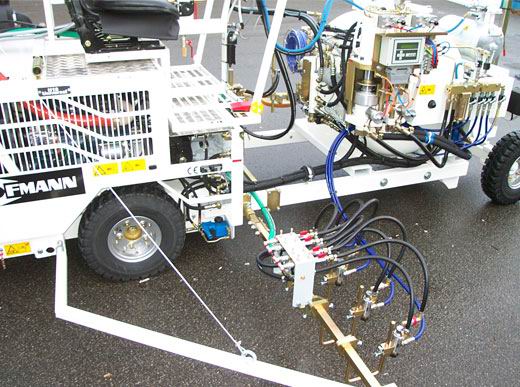

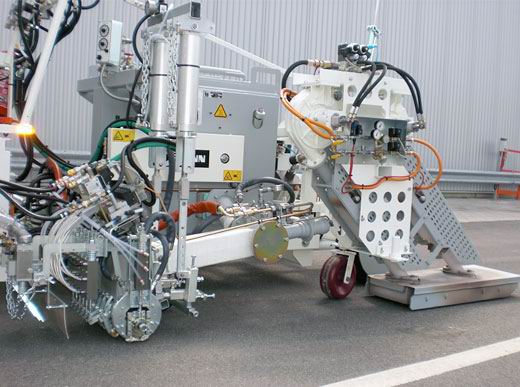

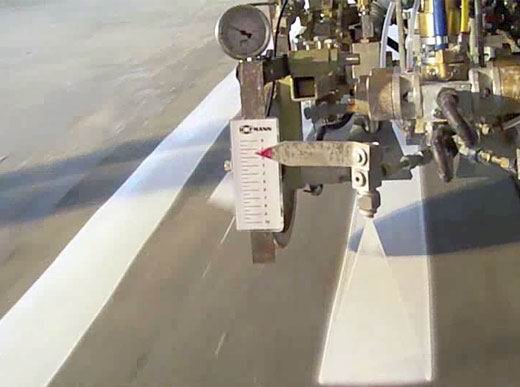

Line width stabilizer - low marking speed - low paint pressure - pointer (spray gun) at the top (Image 1). High marking speed – pointer (spray gun) below (Image 2).

|

|

Double 2-component Airless gun on type H18-1 for 2-component sprayable cold plastics, Airless (pump) M98:2. |

|

|

Enlarged pressurised glass bead container for H18: 220 l. |

|

|

Premarking device. |

|

|

Air pulsed method (Spotflex® system) with extruder for defined agglomerates, performed as exchangeable unit for agglomerate-system using scattering device. |

|

|

Crash Absorber System for truck mounting. |

|

|

Mechanical rot for navigation hydraulically operated for machines H26-3 and H33-3. |

|

|

Outlet tube heated by heat transfer oil and discharge valve controlled pneumatically for thermoplastics using screed box method |

|

|

Movable LUMINOUS DIRECTION SIGN mounted on H18-1. |

|

|

Thermoplastics transfer pump (delivery rate of approx. 120 l/min. at 1,6 m delivery height), e.g. mounted at a H75-1500 roadmarking truck with preheaters (2 x 600 l) as well as pressurised container (500 l) for sprayable thermoplastics. |

|

|

Rotary Brush as alternative to sweeping brush. Hydraulically folding up and down from operators platform. Adjustable in 2 positions (straight or 30°). |

|

|

Arrangement of water cooler between motor compartment and seat support. |

|

|

Lowered rear seat (54 cm to road surface) as well as rear step (22 cm). |

|

|

Movable container for hardener on H33-3 with path-dependent pump (Airless) and 1000 l pressurised container. |

|

|

Air- / gas connection on road marking machines H18-1, H26-3 as well as H33-3 for operating H75/25 unit. |